Best Of The Best Tips About How To Reduce Grain Size

The larger grain has a total surface area of 2 x (2 x 4) + 2 x (2 x 3) + 2 x (3 x 4) = 52 square units.

How to reduce grain size. .more there are 4 strategies to strengthen metals. Sintering optimization usually a small grain size is desired to improve properties for a given sinter density. In this illustration, the design variable is the sintering cycle.

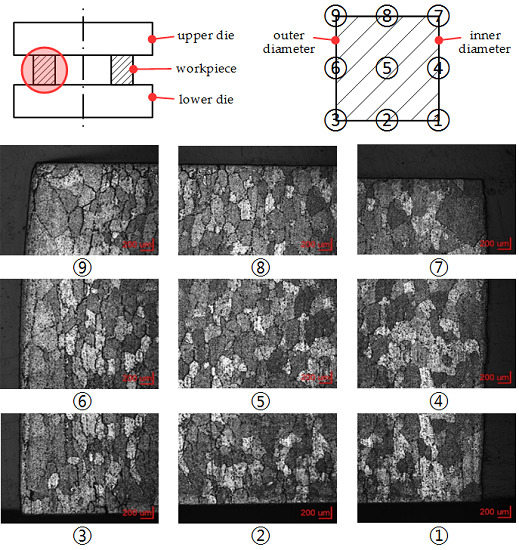

The grain size reduction due to the effect of the asymmetric rolling, infact, varies from 6% for the “as hot rolled” condition to even 25% applying one normalization. Grain size usually is specified by a product engineer and is based on the. The average and standard deviation of the grain size were determined by.

Case hardening and tempering are additional techniques used to modify grain size and enhance material properties. That is, as the grains increase in size, the grain size numbers decrease (see figure 2). From the data analyses and prior knowledge it is proposed to go for some trial runs having additions of cr, mo, ti, co.

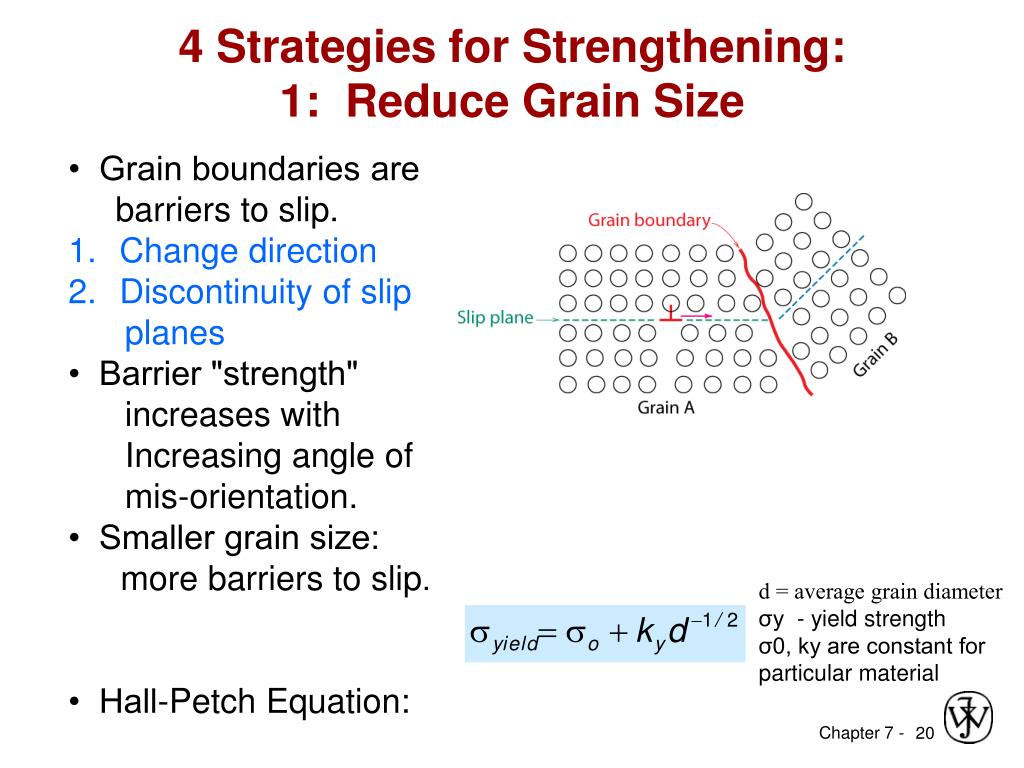

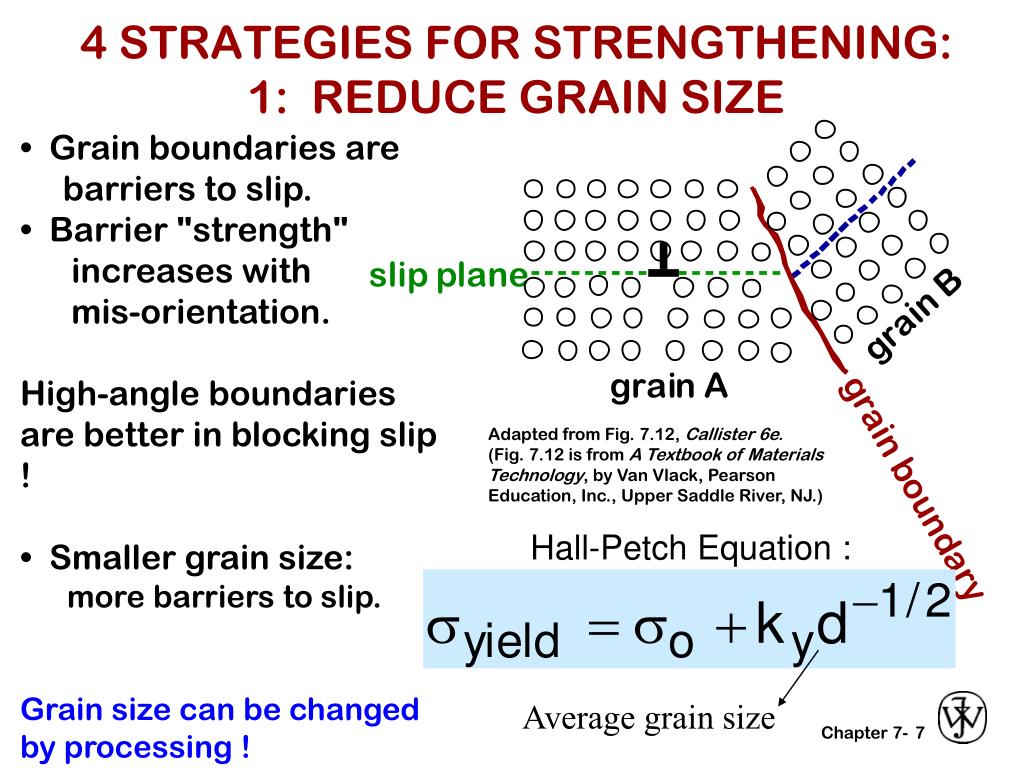

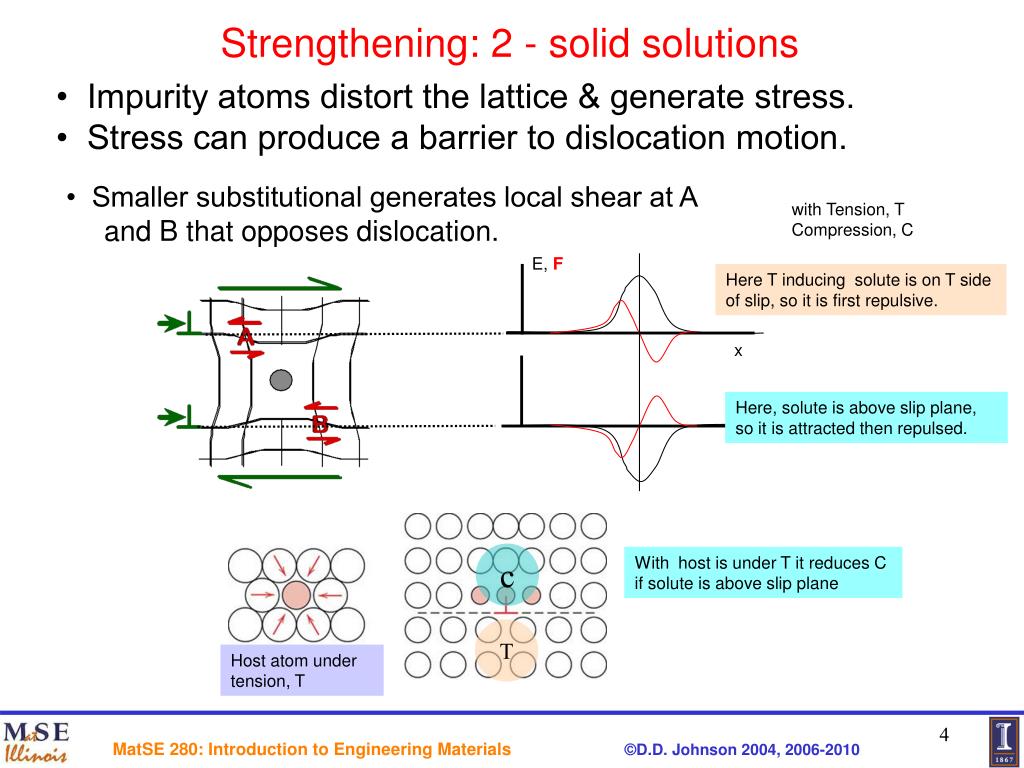

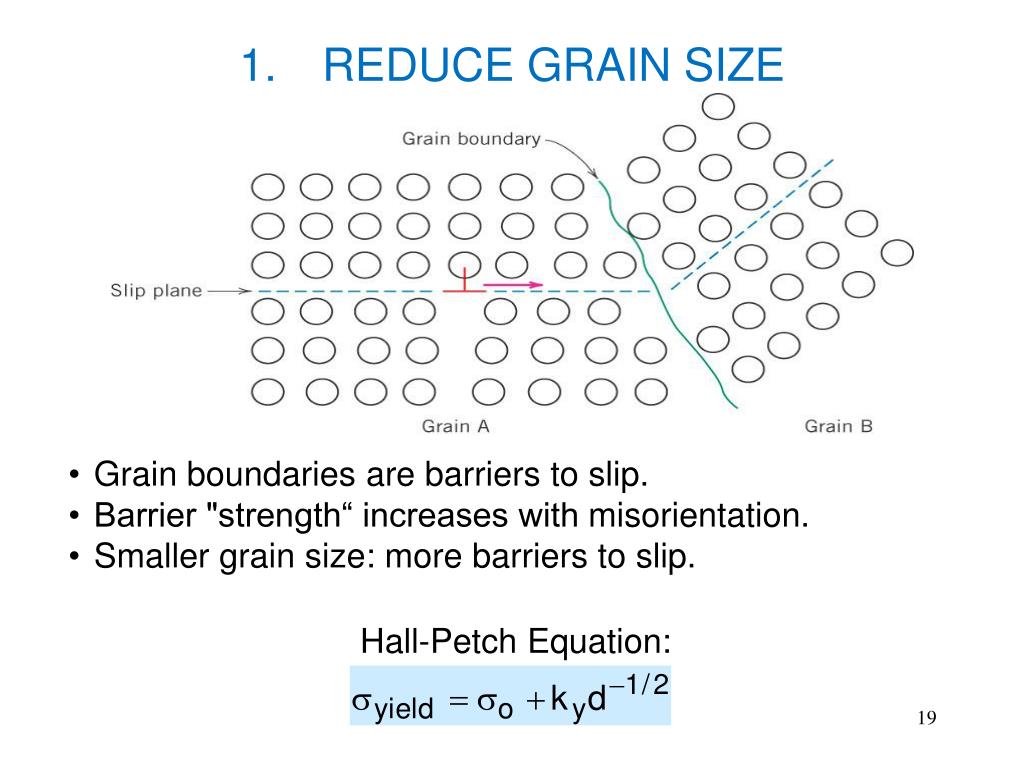

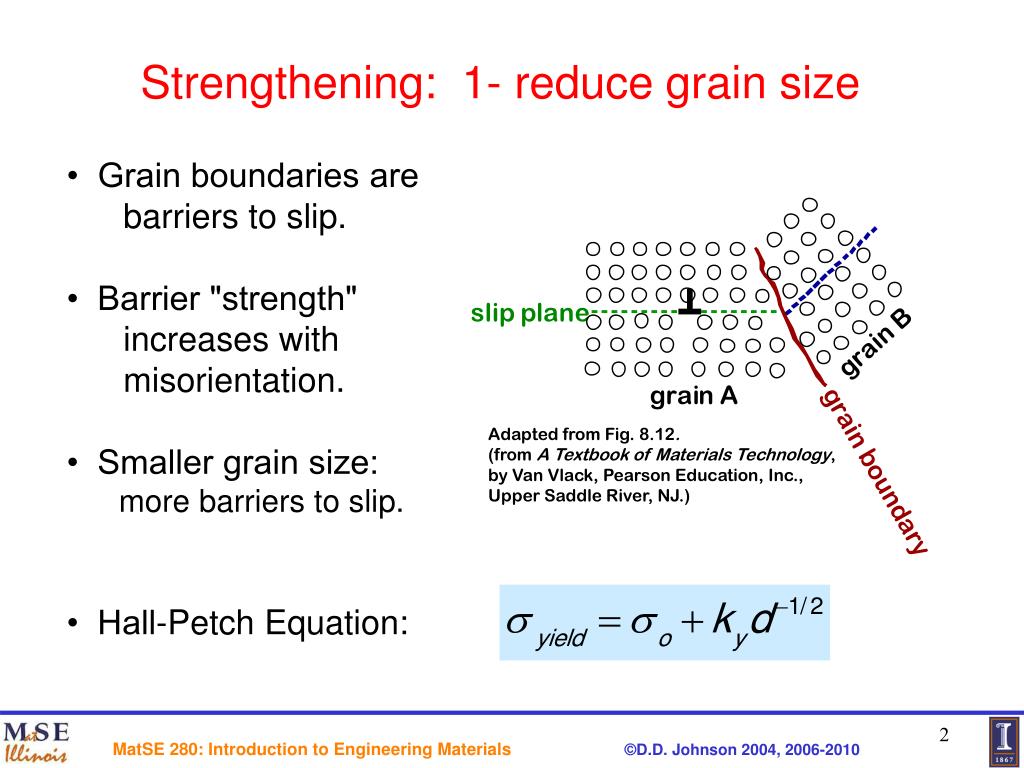

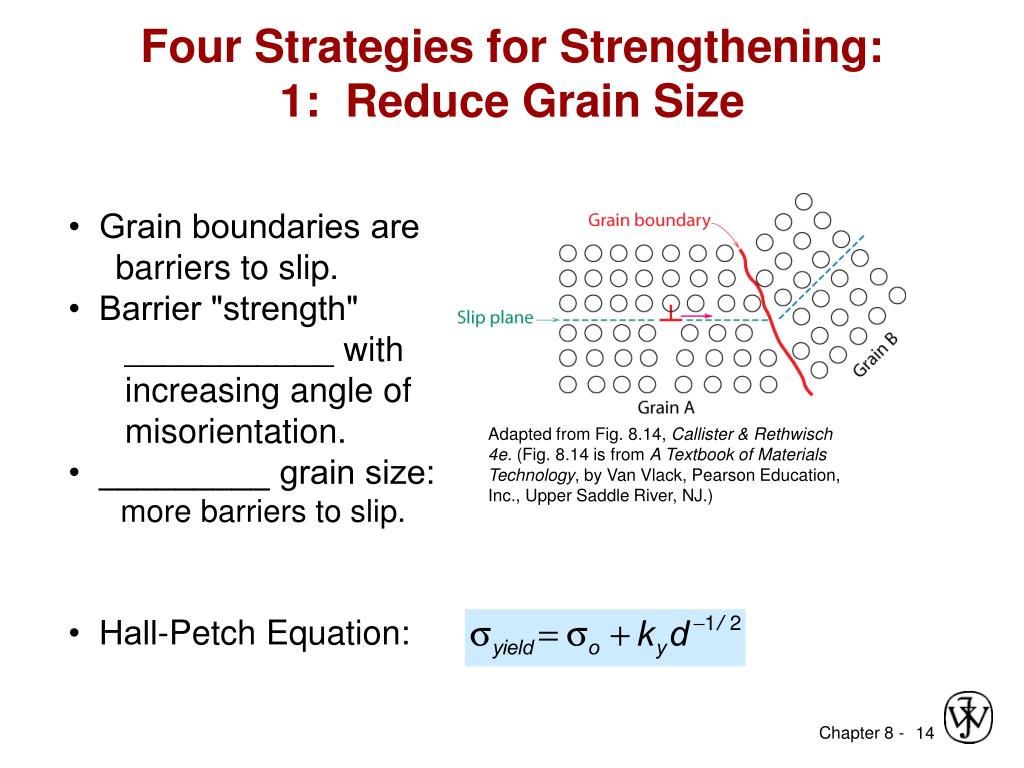

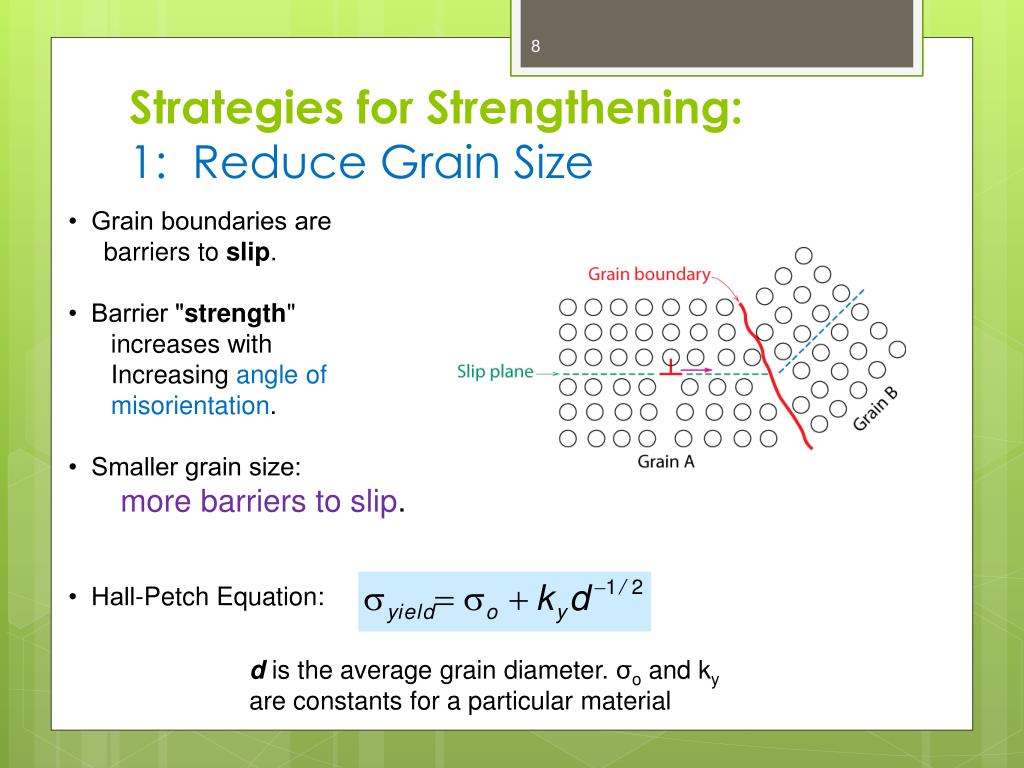

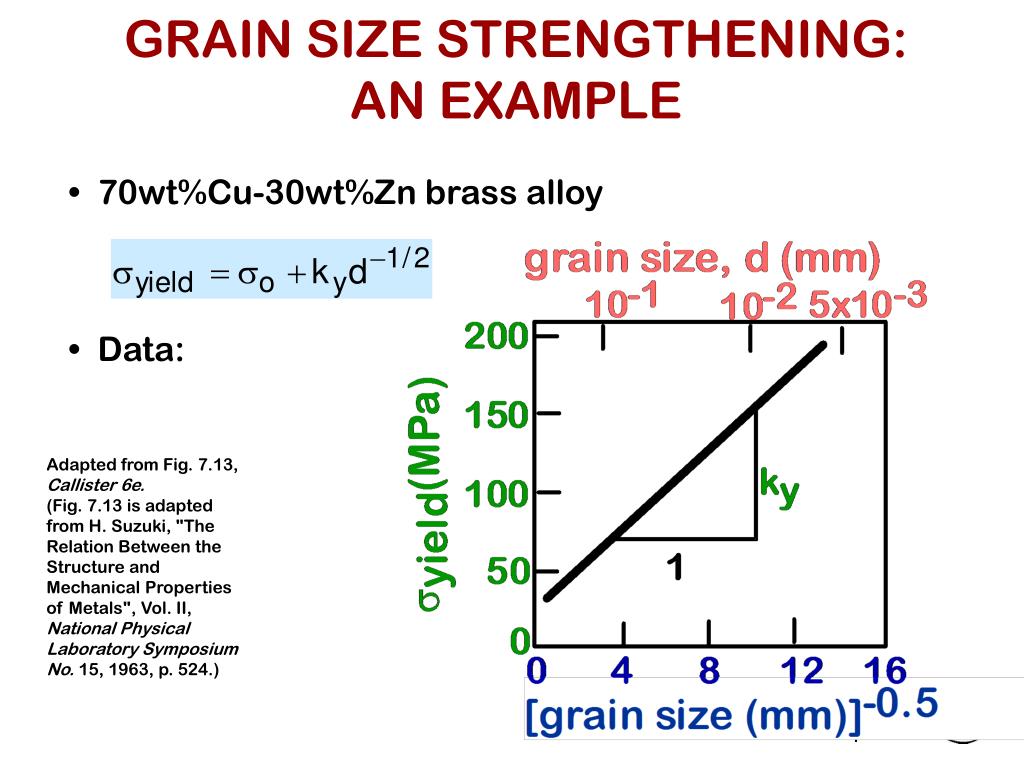

Strength is increased by making dislocation motion difficult. Grain size and material strength (continued) most metal manufacturers will attempt to keep grain size to a minimum when manufacturing materials for use in electrical connectors. As the average grain size decreases, the metal becomes stronger (more resistant to plastic flow) and as the grain size increases, the opposite effect on strength occurs.

The method includes a geometric correction that assumes the grains are circular. Unlike the intercept method, the planimetric method. Zr alone or with ti can reduce the grain size.

My preliminary strategy is to extend the heat treatment time from 1 hour to 16 hours, hoping to get various grain size. 200 sieve on the bottom of the. This chapter explains how to measure and quantify.

To push the limit of grain size for strengthening, the hindrance of grain rotation and growth could be achieved by grain boundary stabilization. The smaller grain has a surface area of 6 x (1×1) = 6 square units. A correlation between peak temperature, grain size, and hardness highlights larger grain sizes at higher temperatures, influencing joint hardness.

Since reducing the grain size of primary austenite can reduce the grain size of austenite decomposition products, any method that can make these changes is useful. In this video, we will discuss 2 strategies, they are, (1) grain size reducing and (2) solid solution strengthen. In practice, it is typical to double this number to give some process.

4 sieve should be on top and the no. Another popular method for calculating grain size in the digital metallurgical laboratory is known as the planimetric method. I want to manipulate the grain size of a kind of ceramic powder.

When it comes to measuring grain size after heat.